Securing Change Projects’ success with Interim Management Expertise

No question, any forecasts about E-Car distribution in Europe were extremely optimistic and never met the reality. Just the Netherlands and Norway seem to be pretty well on track. Even, if there is still no clear picture about the break through, but nowadays, there is no doubt about that electric vehicles will dominate traditional gasoline engines in the mid-term.

Being already aware of this e-mobility challenge for a long time, the automotive industry now got significantly more time pressure as recently expected, due to sudden upcoming potential competition from outside of their particular industry sector, like the Tesla enterprise, or other initiatives in similar directions from Google or Apple.

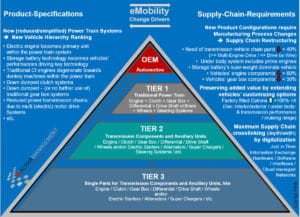

In terms of the variety in electronic vehicle power unit concepts, the Alphamanagement Experts estimate a consolidation towards two basic trends:

- Pure electric power trains will become well accepted with consumers’ “second cars”. Typically second cars are in use for short distance rides below 100 miles a day. E-Vehicles’ given limitations in the cruising range usually significantly excide such 100 miles. So people, going for a change from gasoline powered car to an electric drive system, will not perceive any losses in their habit of comfort. Affected by this e-mobility trend, especially in Europe, will get the markets of Compact Cars, but also Mini-Vans and SUVs, because many of those are in use as the “second cars”.

- Hybrid-vehicle concepts will get advanced towards the dominating power train system for cars being in people’s use as the „first vehicle“. Being not limited in their cruising range, those systems will not require time consuming charging procedures a long a car ride.

With regard to consequences in terms of the added value created along a vehicle manufacturing process on OEM side, the AlphaManagement experts expect a decrease by more than 40%. This is because of various facts mainly driven by tremendous changes at those electric vehicles’ power train.

So a highly performing electric power engine simply can be built from a about 65 single parts, while comparable gasoline engines usually have to get assembled from roughly 650 parts in significantly more complex processes.

Looking at hybrid concepts still using gasoline fired engines, our Experts expect that the electric engine will take over the role of the power trains primary drive unit. The gasoline engine will get downgraded towards a donkey machine, driving a high efficient alternator system to charge the vehicle’s battery.

On the hardware side, the only alternative for OEMs to balance such 40% “added value losses” remains with taking drastic actions to extend the vehicles’ factory fitted options, providing buyers a huge variety of customizing options for their cars’ interior- and exterior equipment.

To stay in the markets as competitive in the future, on product side, our experts see two major challenges the OEMs have to deal with:

First: Passenger cars have to get manufactured always on best in class efficiency level. Any sub-optimal processes, resulting from unchanged traditional supply chain- and assembling workflows, will directly impact costs negatively.

Second: Being able to serve car buyers with a very high variety of interior- and exterior equipment on choice in consistence with their delivery time expectations, OEMs must cross-link all relevant buying- and manufacturing processes with their suppliers at real-time level.

Enablers for the OEMs’ prospective competitiveness are comprehensive plant equipment upgrades and/or reconstructions towards appropriate Machine-to-Machine (M2M) process applications. With regard to such M2M networks, vendors have to prepare their production infrastructure for getting cross-linked to an appropriate supply chain system being operated on real-time basis.

So construction- and machine building firms can expect a massively growing demand in future for production- and logistic systems’ upgrades towards automated M2M communication. But just those companies will benefit from this, providing comprehensive skills in complex control system development being also well experienced with hardware/software system integrations.

Domestic producing suppliers, already heavily stressed by the East-European- and Far-East competition, will get strained with additional pressure, in case they won’t be able to adapt their business capabilities towards networked M2M applications.

Driven by the challenge to offer substantial and pragmatic management solutions within such fast growing areas, AlphaManagement has created the Business Practice “Digital Industry” already in 2013. These experts, combining their excellence in Hard-/Software- /Network- as well as Service matters, support our clients in:

- developing their enterprise’s optimum digitalization strategy

(e.g. in terms of how to keep my enterprise in a sustainable “A-Vendor” position, minimizing the risk of downgrading to a sub supplier from a new rising 360° full service provider) - aligning their enterprise’s procurement- and sales-logistics processes towards the customers’ requirements for adaptive process systems according their future application needs

- upgrading enterprise’s production- and/or ERP-systems to link them to new digital interfaces

- product control systems’ further development from proprietary standards towards cross-linking network solutions

With more than 37 years of business history AlphaManagement is the eldest German Provider for temporary Management Services. Our today’s accomplishments are founded on a wide-spread, long term experience in servicing companies from different sectors of industry, trade/retail and services. Having gained a deep knowledge about multifaceted enterprise process cultures from manifold business sectors, our competence is quickly to understand the clients’ specific needs for best skilled people. With access to 50.000 high skilled Managers and Specialists covering more than 50 countries world-wide via partners with offices in 17 nations, we support our clients along their occupations in finding the “Perfect fitting Experts”.